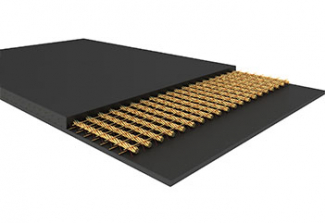

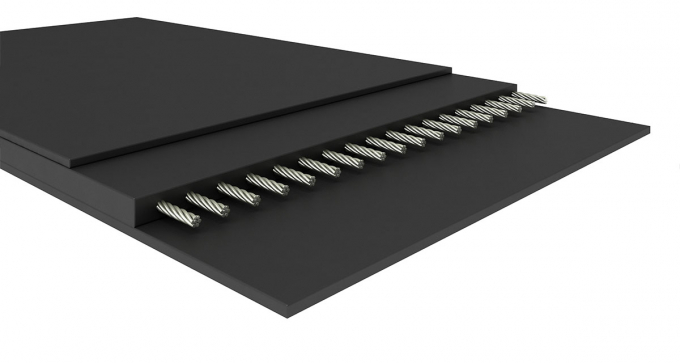

Unisteel – nastro steelcord

SATIBELT®Rubber conveyor belts

Use

Area of operation: long distance and high speeds long conveyor belts for and mines, tunnels, ports, power plants, etc.

Structure

- Description: UNISTEEL is suitable to be used on long distance and elevation conveyor belts, where the cargo transported is significant. With UNISTEEL, thanks to the very low elongation, it is possible to cover large distances, without the obligation to use intermediate counterweights and stations. UNISTEEL belts guarantee a long service life, thanks to the even tension of the metal cables, an excellent cord-rubber adhesion and with a strong passion for forming the basin. The structure of the carcass, less thick than a textile belt, guarantees excellent winding, even on the smallest drums. The safety factor of a metal belt of 6.67 against the 10 of a textile belt, this means that the comparison for the same breaking load highlights the advantage of a metal belt with respect to a textile belt. The joint, unlike the textile belts, can keep up to 100% of the load of that belt, without therefore being a weak part. Another advantage of the metal belts and which can also be regenerated. To avoid longitudinal cuts or to restrict them, the carcass may be protected by metal transversal reinforcements and cutting sensors - the sensor loop. The metal belts are available with different covers: abrasion-resistant, highly abrasion resistant, cut resistant, oil resistant, ice resistant, heat resistant, flame retardant and self-extinguishing pursuant to standards DIN14973-C2 test A for underground use. Can be produced in widths of 800-2400mm and with breaking load up to 5400N / mm

Temperature

- -

Packaging

- -