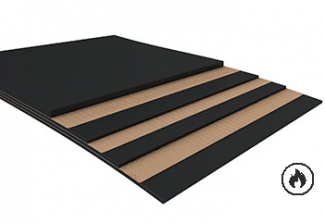

Unicalor – nastro anticalore

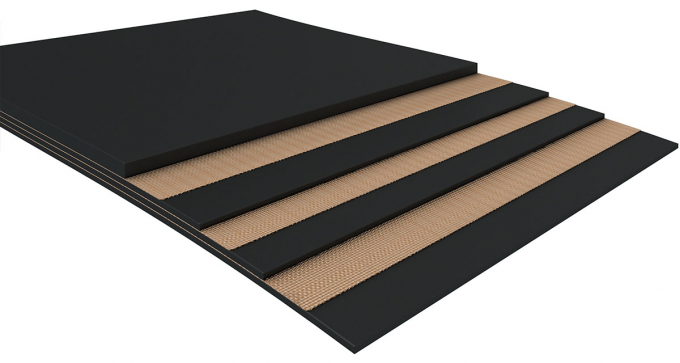

SATIBELT®Rubber conveyor belts

Use

For cement plants, thermal power plants, foundries, steel mills, chemical and steel industries, etc.

Structure

- Types: To decrease the damage to the conveyor belt due to the transport of hot material, we can offer our line of heat resistant belts, where a special cover protects the carcass of your conveyor belt from the high temperatures:

- UNICALOR HR1: The UNICALOR HR1 is suitable for conveying hot material, with a maximum operating temperature of 120°C

- UNICALOR HR2: The UNICALOR HR2 is suitable for conveying hot material, with a maximum operating temperature of 150°C

- UNICALOR HR-OIL: The UNICALOR HR-OIL - is suitable for conveying oily and hot material, with a maximum operating temperature of 130°C and peaks of 150°C (example: asphalt).

- UNICALOR HR3: The UNICALOR HR3 - EPDM based cover is suitable for conveying hot material, with a maximum operating temperature of 180° C and peaks of 400°C. Besides a great resistance to the heat, this cover has also a good abrasion resistance (~130mm3).

Temperature

- Max: 200 °C

Packaging

Special notes

The operating temperatures depend on the temperature of the working environment, size of the transported material and duration of contact. Do not hesitate to call us for more details. The carcass of these conveyor belts is made of a composition of polyester fabrics E in warp and in weft polyamide P, resistant to atmospheric agents such as moisture. This structure ensures a high longitudinal tensile strength and transversal flexibility.

*Produced under DIN22102. Can be supplied in width max. of 2400mm and load of 3150N/mm.